The NEC recommends keeping voltage drop under 3% for optimal performance. Results above this threshold may require larger wire sizes.

The Voltage Drop Calculator ensures electrical systems operate safely by measuring voltage loss across wires using NEC-recommended formulas. Designed for electricians and engineers, this tool calculates wire size (AWG), conductor material (copper/aluminum), and circuit type (single/three-phase) to prevent energy waste, overheating, and equipment damage.

Comply with the 3% voltage drop limit for feeders and branch circuits while optimizing efficiency.

Voltage drop occurs when electrical voltage decreases as current flows through a circuit due to resistance, impedance, or both. This phenomenon is an inherent property of any conductor but must be kept within safe limits to ensure proper functioning of electrical systems.

By calculating voltage drop, you can:

The National Electrical Code (NEC) recommends limiting voltage drop to 3% for branch circuits and feeders, ensuring efficiency and safety.

Excessive voltage drop can result in:

Keeping voltage drop within acceptable limits ensures safe and cost-effective operation of electrical systems.

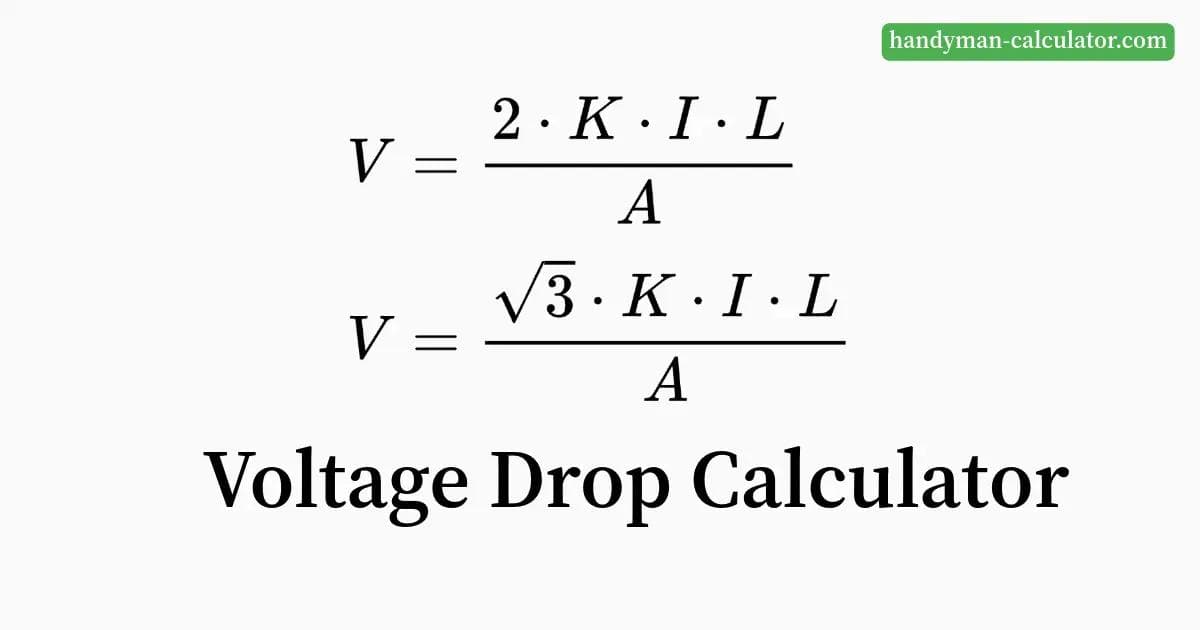

The calculator uses the following formulas to determine voltage drop.

For single-phase circuits, the voltage drop (V) is calculated using:

For three-phase circuits, the formula becomes:

Where:

Calculating Circular Mils (CM) for Wire Sizing:

To determine the required wire size (in circular mils), we use:

The Permitted Voltage Drop is typically 3% of the system voltage.

Power Loss Calculation:

Efficiency Calculation:

Our calculator simplifies the process of determining voltage drop and choosing the correct wire size. Here's how to use it:

Click "Calculate," and the tool will provide the following results:

Scenario: You need to run a 145-foot copper wire to power a shed that will draw 60 amps on a 240V single-phase circuit. You're considering using a 4 AWG wire.

Phase Factor = 2

Conductor Constant (K) = 12.9 (copper)

Current (I) = 60 amps

Length (L) = 145 feet

Wire Area (CM) = 41740 (from a wire gauge table for 4 AWG)

Permitted Voltage Drop = 240V * 0.03 = 7.2 volts

5.37 volts (actual drop) < 7.2 volts (permitted) = Yes, it's acceptable.

Permitted voltage drop would be: 120 * 0.03 = 3.6

Using the same formula above, we get 5.37 volts of drop, which is greater than 3.6. Thus, it is not acceptable.

Using the formula for circular mils, we get:

Looking at the wire size table, we see that we need a bigger wire size of 2 AWG, which has a CM of 66,360.

The National Electrical Code (NEC) recommends a maximum voltage drop of 3% for branch circuits and feeders for optimal efficiency. However, a total voltage drop of up to 5% (including both feeder and branch circuits) is sometimes considered acceptable, though it may still affect equipment performance.

It is essential to minimize the voltage drop as much as possible. Excessive drop can damage equipment. For low-voltage circuits (e.g., sensors), design splits safely with our Voltage Divider Calculator.

"Drop out voltage" usually refers to the minimum input voltage at which a voltage regulator can maintain its specified output voltage. It's not directly related to the voltage drop in a circuit caused by wire resistance.

To find a voltage regulator's dropout voltage, you should consult its datasheet provided by the manufacturer.

No, a 10% voltage drop is generally not okay. It significantly exceeds the recommended 3% limit and can lead to serious performance issues, overheating, and potential damage to equipment.

A 6% voltage drop is also higher than the recommended 3% limit. While it might not be as severe as a 10% drop, it's still likely to cause noticeable problems with equipment performance and efficiency. It's best to address the cause of the voltage drop and aim for a lower percentage.

By using our Voltage Drop Calculator and understanding the principles behind it, you can ensure your electrical projects are safe, efficient, and perform at their best. Don't let voltage drop compromise your equipment or inflate your energy bills.